1.

Load Carring Capacity - @ 50 % of standard capacity.

Load carring capacities given in charts are on the basis of ideal conditions like load is

equally distributed on all wheels, trolley running on horizontal, smooth and leveled surface at a speed below 6 km / hr in ambient temperature @ 30o C.

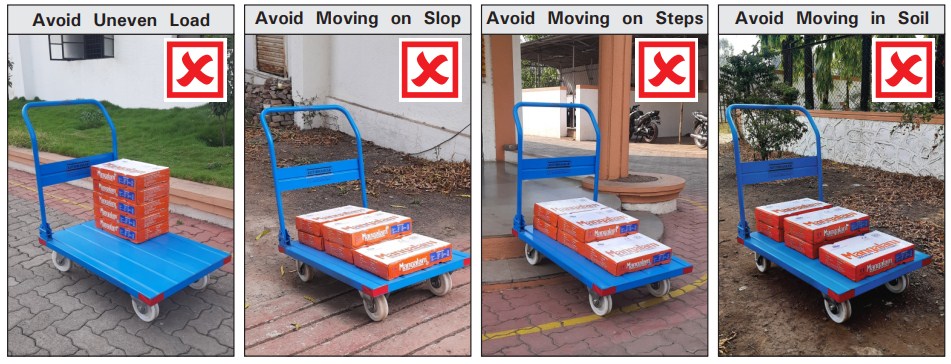

However actually on shop floor many abnormal conditions exists like uneven loading on castors, shock loads on castors, unevenness of shop floor and trolley speed.

Considering above conditions as a thumb rule, load carring capacity of a castor is considered @ 50 % of standard stated capacity.