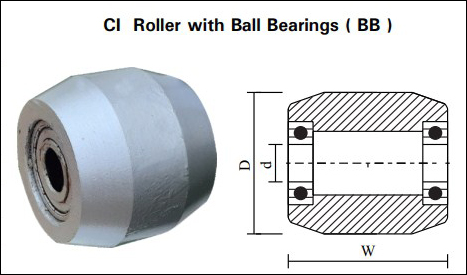

| * CI Rollers | |||

| Roller Size D x W mm |

Bore ID d mm |

Bearing Number | Load Cap Kg |

| 80 x 70 | 20 | 6204 | 800 |

| 80 x 85 | 20 | 6204 | 900 |

| 80 x 90 | 20 | 6204 | 900 |

| 80 x 96 | 20 | 6204 | 1000 |

| 80 x 100 | 20 | 6204 | 1000 |

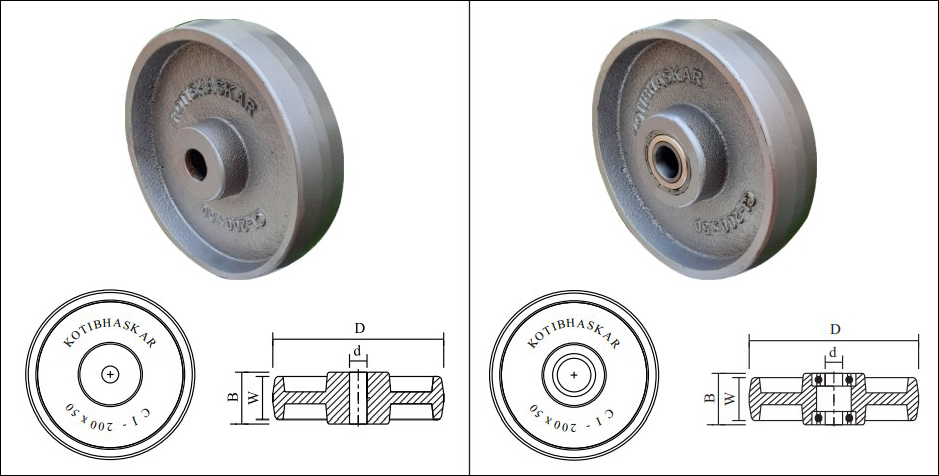

| No. | Description | Wheel Size D x W mm | Boss Width B mm | Bore - ID d mm | Bearing Number | Load Cap Kg |

| 1 | CI - WHEEL - 50 x 25 x 12 - PLB | 50 x 25 | 30 | 12 | --- | 100 |

| 2 | CI - WHEEL - 50 x 25 x 12 - BB | 50 x 25 | 30 | 12 | 6001 | 100 |

| 3 | CI - WHEEL - 63 x 25 x 12 - PLB | 63 x 25 | 30 | 12 | --- | 130 |

| 4 | CI - WHEEL - 63 x 25 x 12 - BB | 63 x 25 | 30 | 12 | 6001 | 130 |

| 5 | CI - WHEEL - 75 x 25 x 12 - PLB | 75 x 25 | 30 | 12 | --- | 160 |

| 6 | CI - WHEEL - 75 x 25 x 12 - BB | 75 x 25 | 30 | 12 | 6001 | 160 |

| 7 | CI - WHEEL - 75 x 32 x 15 - PLB | 75 x 32 | 40 | 15 | --- | 200 |

| 8 | CI - WHEEL - 75 x 32 x 15 - BB | 75 x 32 | 40 | 15 | 6202 | 200 |

| 9 | CI - WHEEL - 100 x 32 x 15 - PLB | 100 x 32 | 40 | 15 | --- | 300 |

| 10 | CI - WHEEL - 100 x 32 x 15 - BB | 100 x 32 | 40 | 15 | 6202 | 300 |

| 11 | CI - WHEEL - 125 x 32 x 15 - PLB | 125 x 32 | 40 | 15 | --- | 400 |

| 12 | CI - WHEEL - 125 x 32 x 15 - BB | 125 x 32 | 40 | 15 | 6202 | 400 |

| 13 | CI - WHEEL - 100 x 40 x 20 - PLB | 100 x 40 | 50 | 20 | --- | 400 |

| 14 | CI - WHEEL - 100 x 40 x 20 - BB | 100 x 40 | 50 | 20 | 6004 | 400 |

| 15 | CI - WHEEL - 125 x 40 x 20 - PLB | 125 x 40 | 50 | 20 | --- | 500 |

| 16 | CI - WHEEL - 125 x 40 x 20 - BB | 125 x 40 | 50 | 20 | 6004 | 500 |

| 17 | CI - WHEEL - 150 x 40 x 20 - PLB | 150 x 40 | 50 | 20 | --- | 600 |

| 18 | CI - WHEEL - 150 x 40 x 20 - BB | 150 x 40 | 50 | 20 | 6004 | 600 |

| 19 | CI - WHEEL - 200 x 40 x 20 - PLB | 200 x 40 | 50 | 20 | --- | 800 |

| 20 | CI - WHEEL - 200 x 40 x 20 - BB | 200 x 40 | 50 | 20 | 6004 | 800 |

| 21 | CI - WHEEL - 100 x 50 x 25 - PLB | 100 x 50 | 60 | 25 | --- | 500 |

| 22 | CI - WHEEL - 100 x 50 x 20 - BB | 100 x 50 | 60 | 20 | 6004 | 500 |

| 23 | CI - WHEEL - 100 x 50 x 25 - BB | 100 x 50 | 60 | 25 | 6205 | 500 |

| 24 | CI - WHEEL - 125 x 50 x 25 - PLB | 125 x 50 | 60 | 25 | --- | 600 |

| 25 | CI - WHEEL - 125 x 50 x 20 - BB | 125 x 50 | 60 | 20 | 6004 | 600 |

| 26 | CI - WHEEL - 125 x 50 x 25 - BB | 125 x 50 | 60 | 25 | 6205 | 600 |

| 27 | CI - WHEEL - 150 x 50 x 25 - PLB | 150 x 50 | 60 | 25 | --- | 700 |

| 28 | CI - WHEEL - 150 x 50 x 20 - BB | 150 x 50 | 60 | 20 | 6004 | 700 |

| 29 | CI - WHEEL - 150 x 50 x 25 - BB | 150 x 50 | 60 | 25 | 6205 | 700 |

| 30 | CI - WHEEL - 200 x 50 x 25 - PLB | 200 x 50 | 60 | 25 | --- | 900 |

| 31 | CI - WHEEL - 200 x 50 x 20 - BB | 200 x 50 | 60 | 20 | 6004 | 900 |

| 32 | CI - WHEEL - 200 x 50 x 25 - BB | 200 x 50 | 60 | 25 | 6205 | 900 |

| 33 | CI - WHEEL - 250 x 50 x 25 - BB | 250 x 50 | 60 | 25 | 6205 | 1100 |

| 34 | CI - WHEEL - 300 x 50 x 25 - BB | 300 x 50 | 60 | 25 | 6205 | 1400 |

| 35 | CI - WHEEL - 150 x 75 x 25 - BB | 150 x 75 | 90 | 25 | 6205 | 1000 |

| 36 | CI - WHEEL - 200 x 75 x 25 - BB | 200 x 75 | 90 | 25 | 6205 | 1300 |

| 37 | CI - WHEEL - 250 x 75 x 25 - BB | 250 x 75 | 90 | 25 | 6205 | 1600 |

| 38 | CI - WHEEL - 300 x 75 x 25 - BB | 300 x 75 | 90 | 25 | 6205 | 2000 |

| 39 | CI - WHEEL - 180 x 50 x 20 - BB | 180 x 50 | 60 | 20 | 6204 | 800 |